Dry vacuum pumps, such as the provac dry pumps, continue to grow in popularity. That’s because they increase the efficiency of production processes, cut on costs among several other benefits. With all the efficiency that comes with a dry vacuum pump, it would be interesting to know how it works, right? After all, it is only through a simplified understanding of how these pumps work that more industry players, especially small and medium enterprises, can adopt them. On this basis, let’s do a breakdown of the technology behind a dry vacuum pump.

The concept

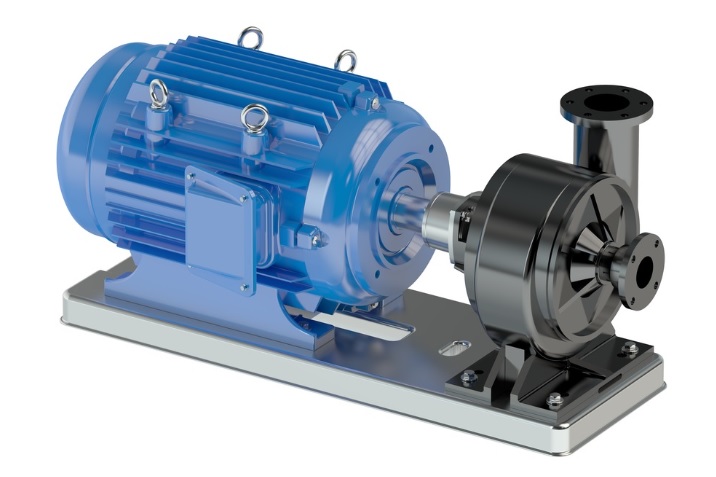

The whole idea behind a dry vacuum pump is to protect against contamination, when multiple systems require a high vacuum environment. To achieve this, dry vacuum systems are designed in such a way that they don’t require any liquids in their operations. To increase operational efficiency, these pumps also utilize vacuum boosters that increase the pump speed.

The working mechanism

The working mechanism of a dry vacuum pump is easy. In this pump, there are two screw-shaped rotors moving opposite to each other. This rotation format allows it to trap whatever is being processed inside the screw chamber, before being pushed into the gas release chamber. This operation has a number of advantages in the production process. For starters, it cuts on the amount of electricity consumed in the process. That’s because, in the newer models of dry vacuum pumps, the amount of medium trapped in the screw chamber at a time is larger. This design also reduces the heat in the compressed chamber, further adding to the efficiency of the process.

In their operation, the rotors generate lots of heat. To guard against this, dry vacuum pumps have a cooling system, that doesn’t require water. Dry vacuum pumps regulate heat through a system where the air is pushed through the rotors at high pressure. The result is that there is an even distribution of temperature throughout the system. The most advanced dry vacuum pumps have the capacity to pump hydrogen, for an even more efficient cooling system that is devoid of cold spots. Even temperature distribution not only ensures an efficient production process, but it also ensures that the pump lasts longer, giving value for money.

Operating a dry vacuum pump

A dry vacuum pump is designed in such a way that it is customizable into specific production processes. In essence, when using one, it is important to engage the services of an expert, who will help you configure it. The working mechanism is simple, but to fine-tune the pump to meet specific needs, a vacuum expert is needed. When properly installed, this technology can lead to huge cost savings especially in electricity costs.

Electricity is a key component in the manufacturing process, and can add or cut on the competitive edge of a business. In essence, using a dry vacuum pump that guarantees up to 60% savings in electricity costs makes lots of business sense. Besides, it guarantees a vacuum environment, which is essential especially in high-value industries like the semiconductor industry.

Leave a Reply