Introduction

When selecting a slip ring, you have to be very specific when you are choosing the models. If you select the wrong slip ring, it can create a series of events that can lead to safety problems, including fatal accidents. So, how can you select a suitable slip ring?

At Moflon, there are many models available, and each one of them has its installation dimensions, installation space, and requirements. Therefore, you have to take careful consideration when selecting a ring to use in your application.

Before we dive into the issues you should consider when you want to buy a suitable ring, it is worth understanding some characteristics of a slip ring, including the different types and specifications of the rings. There are also many factors which you should consider, especially concerning the ring’s working environment.

It is a vital consideration because temperatures differ, and spare parts are not the same for each slip ring application. Installing a wrong slip ring can lead to possible fatal accidents, which makes the task of choosing slip rings of vital importance.

Factors to consider when selecting the perfect slip ring include:

- Mechanical Parameters

Mechanical parameters involve machines that use CNC for every dimension and components for each parameter. For instance, a slip ring can have parameters such as operating speed, channel number, temperature, contact material, humidity, torque, housing material, wire length, and protection levels, among others.

The point mentioned above carries a lot of weight if you want to purchase slip rings, which will function in mechanical environments. The factors men affect how the slip ring will work after installation. In a mechanical installation, the speed at which the slip ring will operate is vital because it directly affects how the whole application will function.

It is especially important if the application will operate at high speeds because you will need a conductive ring to prevent failure by limiting the number of paths.

You should choose a mechanical slip ring wisely because there are several issues that you should weigh in, including the number of rotations. Rotation produces a lot of effects that can adversely affect how the ring performs, and it can even lead to failure in the entire application.

- Slip Ring Materials

The majority of slip rings are made using metals such as gold alloy, silvers, and copper. Therefore, when selecting a slip ring, you should consider the materials which make the slip ring because it will determine the durability of the slip ring.

Slip rings should be made of materials that ensure durability as well as long-lasting performance. However, when considering the materials which make the slip ring, you should also consider the environment in which the ring will operate.

If the environment has corrosives, then you should choose slip rings made of materials that will not corrode or wear quickly.

- Low Maintenance

In most cases, selecting a slip ring normally involves checking performance. However, you should also consider the costs of maintenance. It is advisable to go for slip rings, which have low maintenance even though it is a key component in supplying power to operate machines.

- Size and Construction of the Slip Ring

Slip rings come in many sizes, and each of them has its functions. However, some companies manufacture slip rings capable of being used in various applications.

Therefore, when selecting the perfect slip ring, you should have a clear idea of what you want, including the size of the slip ring.

The structure of the slip ring is also important because manufacturers can build a customized slip ring according to your requirements, thus making it possible to use the slip ring in different applications.

- Humidity

Humidity plays an important role when a slip ring is in operation. You should make sure that at the time you are buying the slip ring, moisture is not very high. It is vital because humidity affects the slip ring’s mechanical insulation resistance.

You should test the ring in an environment similar to the slip ring’s intended operating environment humidity. It will give you an idea of how the ring will work, and in the process, it can help you avoid accidents at the working place.

- Contact Material

During operation, especially in high-speed rotating environments, a lot of heat is generated, and in such a case, the contact material can easily melt.

You should know that for the slip ring to conduct electricity, contact must be created in the contact area, and the area is not large. Therefore, the contact material should have good conductive qualities.

The contact material also affects how the slip ring functions. Therefore, the contact material should have several characteristics, including:

- Wear resistance

- High-temperature resistance

- Low resistance

With such qualities, you can expect the slip ring to function for 24 hours without any interruption. If the contact material is of low quality, it is easy for the slip ring to age quickly and lead to other problems such as poor signal transmission and poor contact.

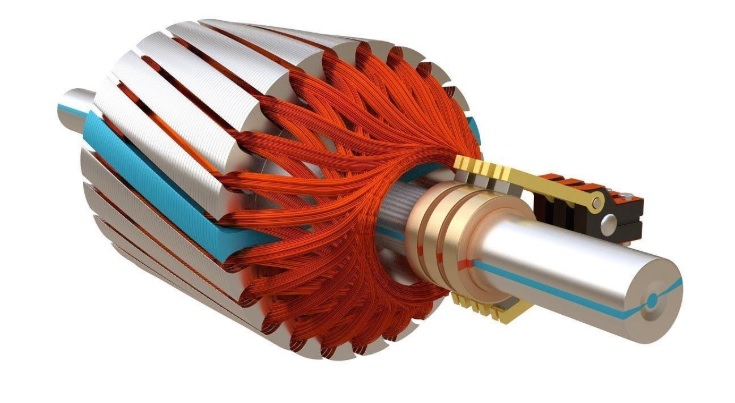

- Brushes

Slip ring brushes are an important part of the mechanism. The brushes are made of metal conductors, but they look like a paintbrush. Brushes are very important in the functioning of a slip ring.

The brushes are responsible for conducting electric current between the rotating wires and stationary wires. When in operation, small areas of the brush known as contact spots contact the commutator.

Before you purchase the slip ring, you should make sure that the contact spots are distributed evenly all over the surface of the carbon brush. It is crucial because it maintains the balance of the brush, and it also averts damage to the commutator.

You should also choose brushes which have high sensitivity because it prevents arcing in the interface between the commutator and the brushes. High sensitivity brushes also maintain power density for DC motors.

Final Thoughts

When selecting slip rings, specifications are important because they will determine how your entire application will function. Therefore, you should not underscore the task of selecting a slip ring. For instance, if you want your slip ring to transmit signals in addition to conducting electric currents, there are certain considerations you should put in place because there are some slip rings that do not have the features of transmitting signals.

Pay attention to basic parameters and functions when choosing slip rings. To get the perfect slip rings, you should visit Moflon and see some of the slip rings we have. A moflon slip ring is not only reliable but durable, and professionals who can guide you to get the best slip ring for your application.

Leave a Reply