Face transplant is one of the most challenging transplant surgeries where the damaged face of a living person is superimposed by an undamaged face of a recently deceased person. There are many patients whose face get completely ruined due to some severe car accidents, or even attacks like bomb acid. Doctors help these patients have a second shot at life with this amazing face transplant surgery. Eminent Plastic Surgeon and face transplant specialist Eduardo Rodriguez said that without a proper face, patients have difficulty in speaking, eating, swallowing, expressing, etc. Till now, only 40 such surgeries have been done across the world.

The most intriguing thing about face transplant is that it’s now collaborating with 3D printing technology. The new collaboration will fuse medicine and surgery with the new technology of 3D printing and 3D imaging. Previously, a new face meant a new identity altogether. Yes, it was possible to bring resemblance of the original person accurately. But with digital printing, accuracy level has ameliorated to a great extent.

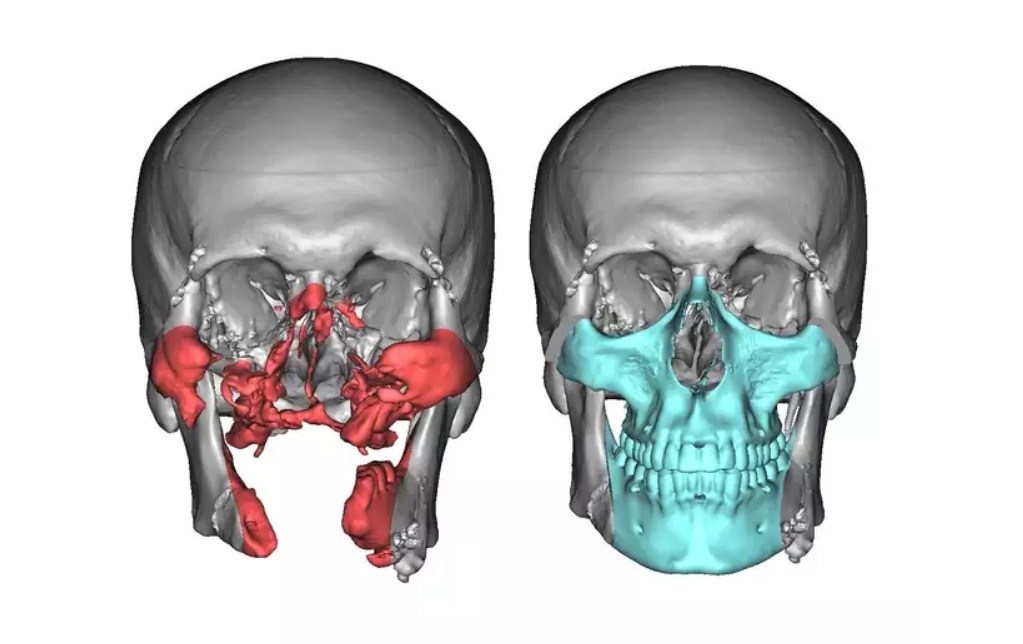

In a severe case, with a self-inflicted gunshot wound, a person named Cameron Underwood got his face completely ruined. His upper and lower jaw bones, all 32 teeth, including gum, tongue, upper and lower eyelids, nose, cheek, facial bones needed to be fully replaced. He had metal plates incorporated in his face through surgery. He was having tremendous problems with speech. He was eating on a feeding tube and a hole in his neck for breathing. He had to wear a surgical face mask. Dr. Rodriguez and his team took several CT scans and X rays from different angles. These images were used to create a picture of the bones, tissues, cavities, contours, etc. Then all these raw data was sent to a company names Materialise. The company is a 3D printing company. The company consolidated the CT scan and X-Ray slices and created a 3D model of the actual face. The digital 3 dimensional model was then converted into slice files that can be read by a 3D printer. The printer then creates a face form from all the relevant slices, data and other 3D renderings.

An SLS 3D printer was used for the purpose. According to a Materialise engineer, the material used was stronger which was “essentially a white almost talcum powder [consistency] spread in a heated chamber”. The main challenge of these operations is to get a donor organs.

Leave a Reply